VDA 5050: Standardized interface for AGVs, AMRs, and master control systems

The big overview of VDA 5050 as a standardized interface for AGVs, AMR and master control. Explained in a simple and easy-to-understand way.

9 min read

Innok Robotics

12-09-2025

Innok Robotics

12-09-2025

A stable, transparent material flow is the basis of any efficient production and intralogistics system. If parts, semi-finished products, containers or pallets are not in the right place at the right time, this results in downtime, search efforts, excess stock or expensive additional shifts. This is precisely where material flow analysis comes in.

Material flow analysis is the systematic recording and evaluation of all transport processes, storage and waiting times in the company with the aim of uncovering weak points in the material flow and making potential for improvement visible.

In this article, you will find out exactly what a material flow analysis is, what objectives it pursues, which methods and key figures are used in practice and what a typical procedure in industry and logistics looks like. You can also read about the role that material flow analysis plays in the decision to use forklift trucks, the classic tugger train or autonomous mobile robots (AMR) and how to avoid typical mistakes.

Material flow analysis is a logistics planning process that examines all movements and stays of materials within a defined system. For example, the following are considered

The aim is to record transportation processes, storage and waiting times in full, display them graphically and evaluate them in terms of effort, costs and time.

A distinction is typically made between

Transport relationships, their direction and sequence are shown, but without quantities. This reduced view helps to fundamentally understand complex networks.

In addition to the transportation relationships, quantities, frequencies, times or costs are also stored. This makes it possible to identify particularly critical flows, such as large quantities over long distances.

The transparency gained in this way forms the basis for optimization measures, layout adjustments, automation solutions or investment decisions.

A material flow analysis always has several objectives at the same time. The most important ones include

Reduction of throughput times

Materials should run through the processes with as little waiting and idle time as possible.

Reduction of transportation and logistics costs

Unnecessary transportation, detours or inefficient means of transport become visible and can be eliminated.

Optimum utilization of space and resources

Bottlenecks in storage areas, overloaded transfer points or underutilized areas are identified.

Increased process stability

Frequent disruptions, ad hoc transports or improvised emergency solutions are identified and replaced in a structured manner.

Increased transparency and predictability

Objective decision-making bases for investments and automation projects are created instead of gut feelings.

Preparation of layout changes and automation projects

Anyone planning new halls, converting existing areas or introducing transport robots needs a reliable basis for defining sensible routes, buffers and interfaces.

In short: a good material flow analysis answers the question of where and why material flows are unnecessarily expensive, slow or prone to faults today and how this can be systematically improved.

In order for a material flow analysis to deliver reliable results, the right data must be collected and converted into meaningful key figures. Typical examples include

Tools such as from-to matrices or distance-intensity diagrams present these key figures in a compact form. Material flows with high volumes over long distances are thus immediately visible and often highlight the most attractive starting points for optimization or automation measures such as the INDUROS autonomous transport robot.

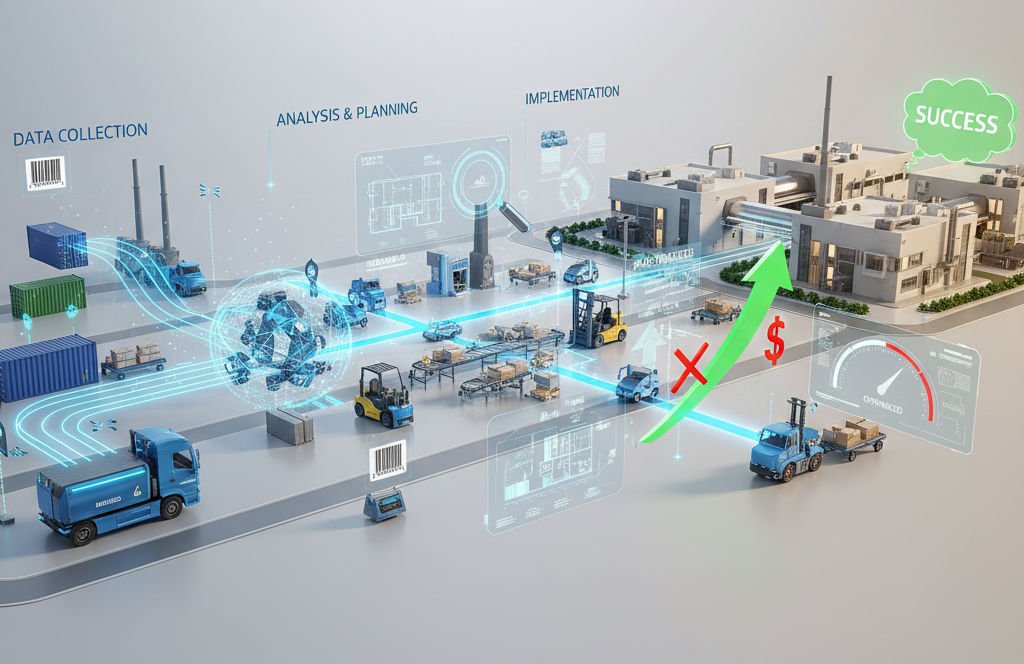

In practice, a multi-stage procedure that can be applied regardless of company size and industry has proven its worth:

It starts with a clear question:

At the same time, the system boundary is defined, i.e. the area to be considered in the material flow analysis.

In the next step, processes, stations and routes are recorded:

This is often done through inspections, interviews on the store floor and evaluation of existing documents.

Real transaction data is now determined. Sources include

It is important to look at representative periods, such as several weeks including seasonal peaks.

The collected data is processed in a structured manner, for example as:

This creates clear actual images that give all those involved the same view of the material flow.

Based on this visualization, bottlenecks, waste and risks can be identified, for example:

The first areas for improvement are prioritized here.

Measures are developed from the identified weaknesses, such as

Scenarios are often compared, for example "forklift operation" and "AMR automation".

Finally, measures are prioritized, implemented and their impact tracked, for example with:

This makes material flow analysis a recurring management tool, not a one-off project.

Classic lean methods and modern digital tools are combined in material flow analysis.

Direct observation on site to understand real processes, detours and informal routines.

Visualization of processes, material flows and information flows in a simple, understandable form.

Lean method for visualizing the value stream, including material and information flows, in order to make waste in the process visible.

Tabular representation of material flows with quantities or transport frequencies between sources and sinks.

Combination of transportation intensity and distance to identify material flows with large quantities over long distances.

Focus on parts or flows with the greatest impact on costs or throughput.

Representation of the paths of a product or employee in the layout. Frequent crossings and loops are an indicator of waste.

Graphical representation of material flows in which the width of the arrows corresponds to the quantity transported. Particularly suitable for differentiating between main flows and secondary flows.

Software for creating and evaluating layout variants including material flows.

Discrete-event simulations in which real data is transferred to a model in order to test future scenarios, for example with changed quantities or the use of transport robots.

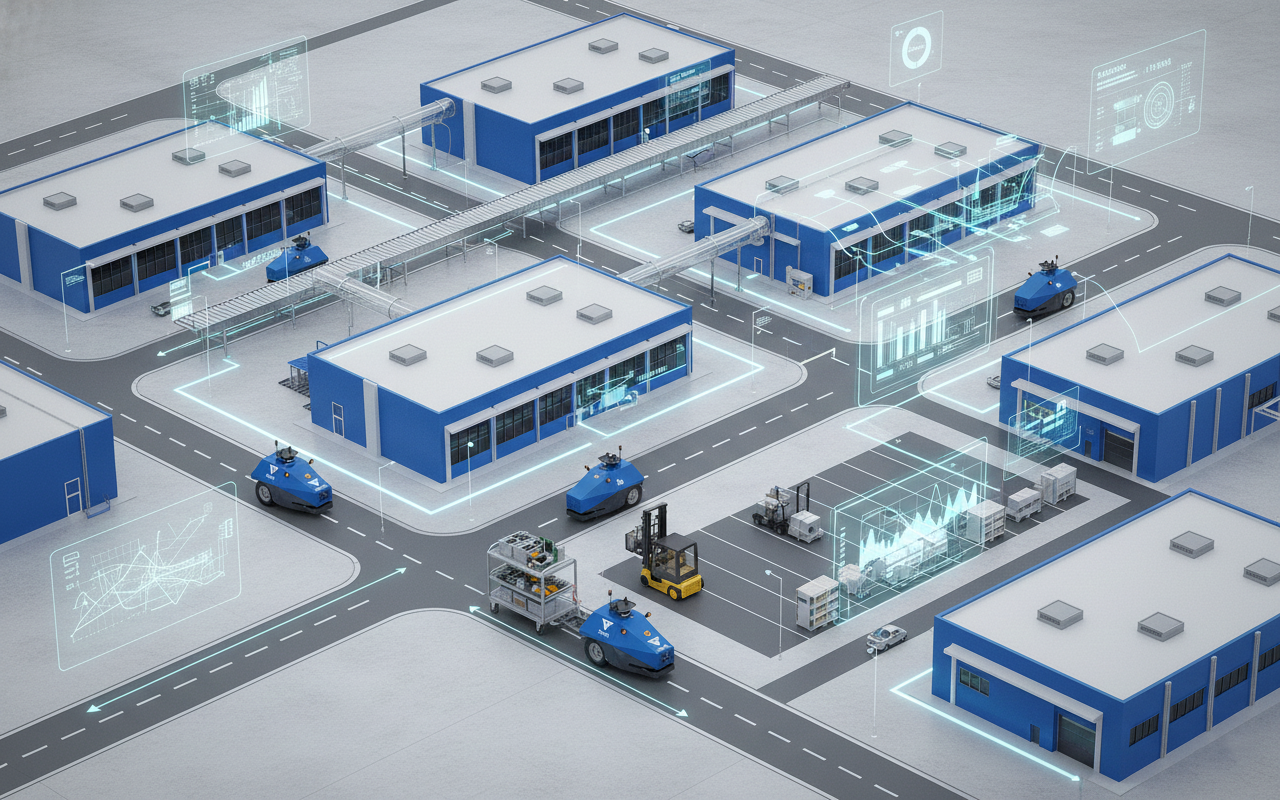

Even during operation, control systems for transport robots or AGVs provide valuable data for ongoing material flow analysis.

Material flow analyses are always used when processes are complex or framework conditions change. Typical examples are

Which areas belong together spatially, which routes should be short and where is automation worthwhile?

Historically grown processes often lead to unnecessarily long distances, intermediate storage facilities and isolated solutions.

Which routes are suitable for clocked tours, which for flexible autonomous systems?

For example, from line production to cell production, introduction of one-piece flow or increased use of just-in-time and just-in-sequence concepts.

More variants and smaller batch sizes increase the demands on the material flow and make weak points visible.

Material flows across the factory premises, between halls or to outdoor warehouses, where weather influences, different floor qualities and safety requirements have to be taken into account, are particularly challenging. Autonomous transport robots such as an INDUROS can be a decisive success factor here, as this robot can drive autonomously both indoors and outdoors.

In these scenarios in particular, a proper material flow analysis determines whether subsequent automation with AGVs, tugger trains or autonomous mobile robots can develop its full potential.

A material flow analysis not only answers the question of where improvements can be made, but also what type of transportation solution is suitable for this. It creates the basis for evaluating whether, for example, a tugger train, classic driverless transport systems or autonomous mobile robots are the best option.

Typically, the analysis shows:

Route trains or clocked routes with an AGV or AMR are suitable here.

Autonomous mobile robots show their strengths in areas with frequently changing routes or individual transports triggered by employees.

These include transfer points at machines, consolidation zones, loading ramps, incoming goods and outgoing goods.

It becomes particularly exciting when material flows leave the building: Transportation between halls, across the yard, to outdoor warehouses or directly to outdoor production facilities. This is where traditional indoor solutions often reach their limits, while specially designed AMRs such as the INDUROS work reliably even on poor floors or in outdoor areas.

Ideally, the material flow analysis is the starting point of a roadmap, at the end of which there is scalable automation with the right combination of tugger train and autonomous mobile robots.

The costs of a material flow analysis depend in particular on

In practice, projects range from lean, focused analyses of individual lines to extensive location analyses with simulation. It is not so much the absolute project size that is of interest, but the ratio of project costs to savings achieved, for example through

In many cases, material flow analysis and the measures derived from it pay for themselves within a few months to a few years, especially if they are linked to specific automation steps or layout improvements.

In order for a material flow analysis to unfold its full benefits, you should consciously avoid a few stumbling blocks:

If objectives are not precisely defined, data is collected without focus and results remain abstract. Better: clearly defined areas and unambiguous target values.

Average throughput times or average transport volumes conceal peak loads and bottleneck situations. Also analyze peak loads, seasonal effects and special cases.

Many plants have "shadow logistics" consisting of spontaneous trips, emergency transports and detours. These must be taken into account, otherwise an important part of reality will remain invisible.

Data alone does not tell the whole story. Anyone who works with the material flow on a daily basis knows the causes and practical hurdles. Involve this expertise at an early stage.

A pretty diagram is useless if no decisions are made on the basis of it. Plan from the outset how measures are to be evaluated, prioritized and implemented, for example with regard to possible transport robots or tugger train concepts.

A material flow analysis is far more than just a snapshot of internal transportation. It creates transparency about routes, quantities, times and costs, uncovers weak points and provides a sound basis for investments in layout, organization and automation.

A systematic approach, clearly defined objectives and a combination of qualitative and quantitative methods can:

This makes material flow analysis a strategic tool for companies that want to gradually raise their intralogistics to a higher performance level - from the first spaghetti sketch to highly automated, intelligently controlled material supply.

If you have already opted for an autonomous transport solution such as the AMR INDUROS, the experts at Innok will also be happy to help you calculate the individual benefits of switching to autonomous transport processes.

The big overview of VDA 5050 as a standardized interface for AGVs, AMR and master control. Explained in a simple and easy-to-understand way.

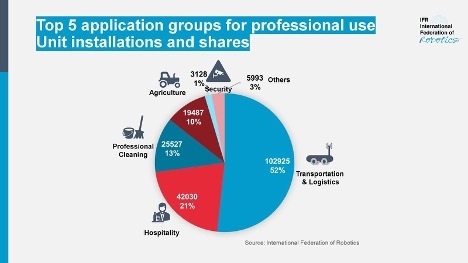

Highest safety standards - safety without compromise

Global boom in service robotics - what the IFR figures show Professional service robots are growing dynamically worldwide. According to the...